Belt Refurbishment & Recycling

We at MES strive for continual improvement for ourselves and our customers. We are always looking for ways to save our customers money and have invested in equipment that can provide a belt refurbishingfacility that will allow used belts to be re-utilised in other areas of your operation.

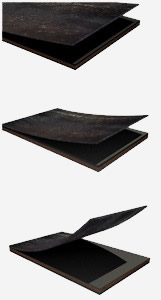

MES can save you money. By removing the worn/pitted running surface and trimming the width, a belt that would have usuallybeen scrapped can be re-fitted in a less demanding area, saving you the cost of waste removal and purchasing a new belt in one go.

Please view the short animation below, to see how you can save money with our refurbishing facility.

Not only can we refurbish your belts to be recycled within your business, we do so producing ZERO waste.

MES can also offer an environmentally friendly solution of disposing of unwanted second hand and scrap belt, used rubber screen mats and rubber wear liners.

During the refurbishing process, waste rubber is generated from the worn surface and reducing the width of belts that are to be re-utilised on different conveyors.

MES are always looking for ways to reduce the waste and environmental impact of our business activities. To address this, we take the waste rubber and granulate it into different sizes that can then be utilised in other areas such as equestrian surfaces, animal welfare, construction products and also refining back to the main rubber elements of oil and carbon black.#

MES can offer the complete belt service of “Supply, Fit, Vulcanise, Remove and Recycle”

MES is burning the trail in belt refurbishing. We lead – where others follow!

Please contact a member of our team to discuss the refurbishing and recycling possibilities at your site.

Location

MES International

Walton New Road

Bruntingthorpe

Lutterworth

LE17 5RD

Company Registration Number 1556587 - Vat Number GB 355 3697 25

Web Design Leicester